Ever wondered how nitrogen, a crucial gas in various sectors, is produced? I wanted to tell you about a neat technology called molecular sieve nitrogen generation. This method relies on small filters known as molecular sieves that separate nitrogen gas from other air gases.

This type of filter is packed into beds inside a molecular sieve nitrogen generator. As air is forced into the generator, molecular sieves trap oxygen, carbon dioxide and other undesirable gases, allowing only pure nitrogen gas to pass through. This itself generates its own cycle, ensuring there is always a high quality nitrogen supply for businesses.

Nitrogen is an essential nutrient for many industries, and many businesses that require nitrogen can save costs by having a guaranteed supply of nitrogen from an on site nitrogen generator. Producing nitrogen on-site allows companies to eliminate the need to purchase costly nitrogen tanks or cylinders, saving both time and money.

Molecular sieve technology, nitrogen generation following purity trademark. The generator is equipped with molecular sieves that are designed to completely eliminate impurities from the air, meaning that the nitrogen is of superior quality. This nitrogen generator is important in fields such as healthcare and aerospace, where the use of pure nitrogen is vital for safety and accuracy.

Molecular sieve technology for making nitrogen is superior to other methods in terms of efficiency and effectiveness. Molecular sieve nitrogen generator are a more streamlined and cost effective solution for businesses compared to older approaches such as cryogenic distillation or pressure swing adsorption.

Furthermore, maintenance requirements for molecular sieve generators are minimal and their service life is long, making them a wise investment in nitrogen generation equipment for companies. Today, molecular sieve nitrogen generators are being selected by more industries worldwide due to their superior capability and stable production.

Molecular sieve nitrogen generators by Hengyetong in electronics industry helps prevent oxidation during manufacturing process and ensures quality in electronic parts. Likewise, in healthcare, there are also these generators for maintaining sterile environments in hospitals and labs, where there it is crucial to provide pure nitrogen for patients’ benefits.

With more than 30 years of dedicated experience, we are recognized as a high-tech enterprise specializing in the application research and manufacturing of air separation gas equipment, making us a trusted leader in the PSA gas solutions industry.

Recognized as a provincial high-tech enterprise, we combine certified technical expertise with a forward-thinking global strategy, delivering the most appropriate and advanced gas separation solutions to customers worldwide.

Committed to continuous R&D and innovation, we adopt the development philosophy of "integrating front-end technology to build a world brand," ensuring our products meet the highest standards of performance and reliability for international markets.

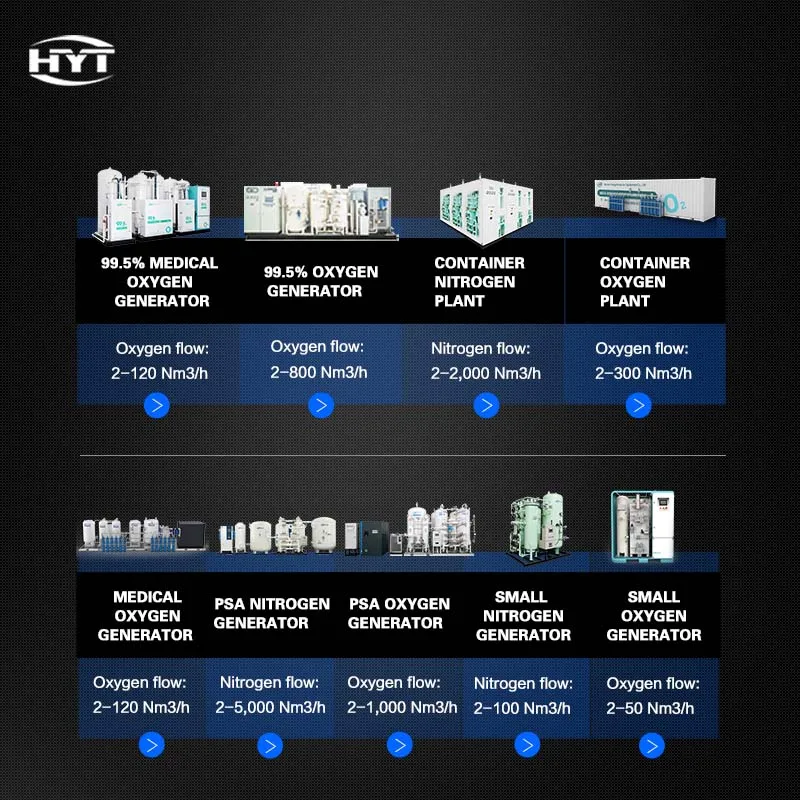

We provide a complete range of advanced gas systems, including Medical Oxygen Generators, High Purity Oxygen Systems, Nitrogen Generators, and CO₂ Removal Equipment, offering integrated and economical solutions for diverse global needs.