All over the world, oxygen cylinders are extremely important in hospitals. They provide oxygen to patients who cannot breathe. Today we will go inside a Hengyetong oxygen cylinder plant to see how these unique devices are knitted together.

The materials are then formed and welded to create the cylinder. This is an involved process that requires skill to ensure that the cylinder is strong and leak-free. The cylinder is then cleaned and painted to prevent rust and corrosion after it’s been formed.

At Hengyetong, technology plays a key role in the production of the life-saving oxygen cylinders. We use modern machinery to assist in the manufacturing process and ensure our cylinders are built to specification. This means we can produce more cylinders, faster, meeting increasing demand for these life-saving devices.

With an increasing population with longer life expectancy, Oxygen Cylinder demand is increasing in healthcare industry. This unequivocally reflects the necessity to have more oxygen cylinders as hospitals grapple to keep up with the demand and we at Hengyetong are working 24/7 and running against time to enhance our production to meet the needs of hospitals.

We partner with health systems to gain insight into their unique needs and develop customized solutions. We are able to meet the increasing demand for oxygen cylinders so that patients get the oxygen they need to remain alive, and this is only possible by real-time improvisation of our procedures.

Committed to continuous R&D and innovation, we adopt the development philosophy of "integrating front-end technology to build a world brand," ensuring our products meet the highest standards of performance and reliability for international markets.

We provide a complete range of advanced gas systems, including Medical Oxygen Generators, High Purity Oxygen Systems, Nitrogen Generators, and CO₂ Removal Equipment, offering integrated and economical solutions for diverse global needs.

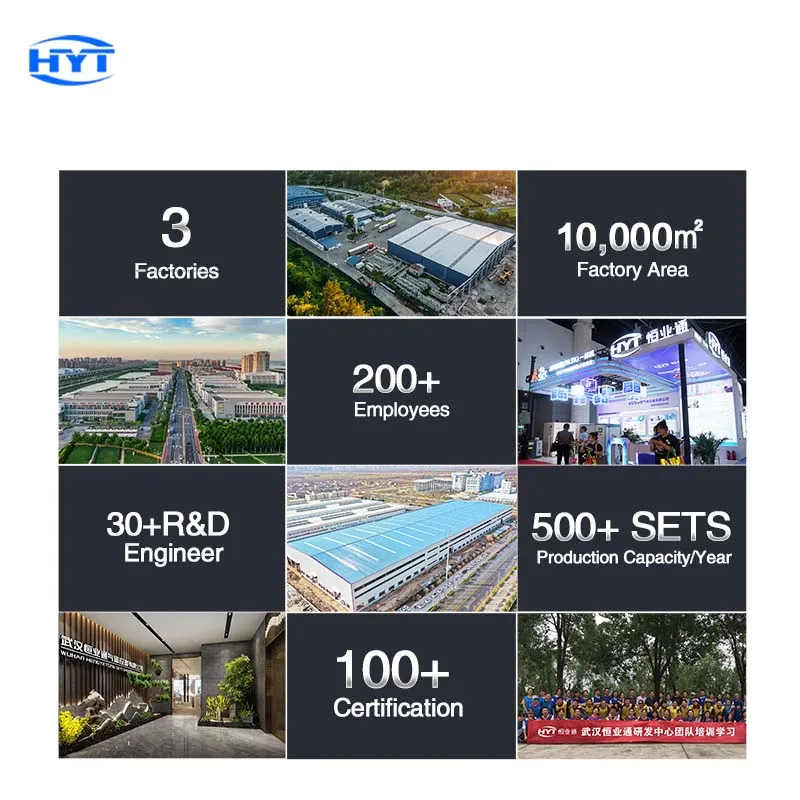

With more than 30 years of dedicated experience, we are recognized as a high-tech enterprise specializing in the application research and manufacturing of air separation gas equipment, making us a trusted leader in the PSA gas solutions industry.

Recognized as a provincial high-tech enterprise, we combine certified technical expertise with a forward-thinking global strategy, delivering the most appropriate and advanced gas separation solutions to customers worldwide.