Oxygen from pressure swing adsorption is a method used to remove oxygen from other gases in the air in order to produce ultra-pure oxygen. Which lead us to learn more about pressure swing adsorption. Pressure swing adsorption uses a specific material known as an adsorbent to separate oxygen away from nitrogen and other gases. They screen out nitrogen molecules while allowing oxygen to pass through. By switching pressure from high to low, the adsorbent is able to release the trapped nitrogen while keeping the oxygen in a ready state for use.

Pure oxygen produced by pressure swing adsorption is interesting to know. We adjust the pressure and temperature in the adsorbent to regulate the quantity of nitrogen that is absorbed, leaving around 90-95% pure oxygen. The necessity of such pure oxygen is critical for numerous applications, including in the medical field and industrial processes.

Sure there are many nice things about producing oxygen via pressure swing adsorption. It is an economical and energy-efficient process that requires no additional chemicals. The mobile 20 Series is compact and plug-and-play, so it’s perfect in a small-room setup or mobile rigs. Also, it is environmentally friendly because it does not litter dangerous waste.

If you want the best output from pressure swing adsorption you need to adjust the system. By precisely modulating the pressure and temperature, the oxygen can be made purer and the energy input reduced even further. Additionally, it is necessary to periodically monitor and service the adsorbent material to ensure that everything is functioning properly.

My knowledge is based on data collected up until October 2023 and studying its applications in medical and industrial areas demonstrates how versatile this technology is. In the medical field, a pressure swing adsorption channels oxygen to sick patients or during surgeries. It’s used in factories for cutting metal, welding and chemical processes that require high-purity oxygen.

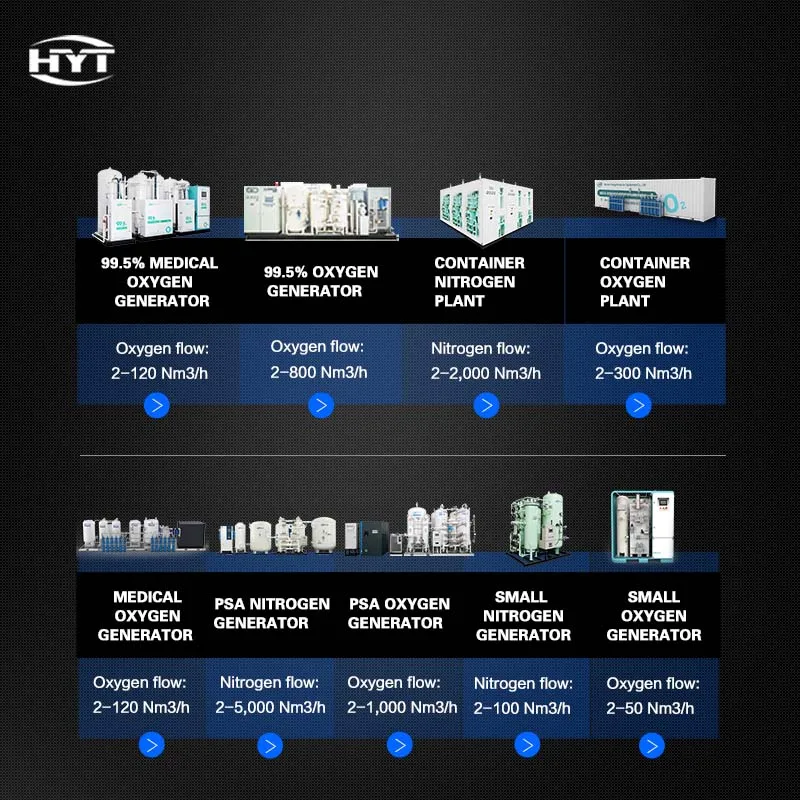

We provide a complete range of advanced gas systems, including Medical Oxygen Generators, High Purity Oxygen Systems, Nitrogen Generators, and CO₂ Removal Equipment, offering integrated and economical solutions for diverse global needs.

With more than 30 years of dedicated experience, we are recognized as a high-tech enterprise specializing in the application research and manufacturing of air separation gas equipment, making us a trusted leader in the PSA gas solutions industry.

Recognized as a provincial high-tech enterprise, we combine certified technical expertise with a forward-thinking global strategy, delivering the most appropriate and advanced gas separation solutions to customers worldwide.

Committed to continuous R&D and innovation, we adopt the development philosophy of "integrating front-end technology to build a world brand," ensuring our products meet the highest standards of performance and reliability for international markets.