Automatic Low Cost High Purity Certificated Nitrogen Gas Generation Plant PSA Industrial Nitrogen Generator

- Overview

- Recommended Products

Introducing, the latest innovation from Hengyetong - the Automatic Low Cost High Purity Certificated Nitrogen Gas Generation Plant PSA Industrial Nitrogen Generator. This cutting-edge machine is designed to provide a reliable and cost-effective solution for businesses in need of high purity nitrogen gas.

The Nitrogen Gas Generation Plant is equipped with a Pressure Swing Adsorption (PSA) system, which efficiently separates nitrogen from the air to produce a constant supply of high purity nitrogen gas. This eliminates the need for traditional nitrogen gas cylinders, reducing costs and ensuring a steady supply of nitrogen for various industrial applications.

One of the key advantages of the Hengyetong’s Nitrogen Generator is its automatic operation feature. The system is fully automated, allowing for easy and hassle-free operation. Simply set the desired nitrogen purity level and flow rate, and the machine will do the rest. This not only saves time and labor but also ensures consistent and reliable performance.

Furthermore, the Nitrogen Gas Generation Plant is built to meet the highest quality standards. It is certificated to guarantee the purity of the nitrogen gas produced, making it suitable for a wide range of industrial applications. Whether you need nitrogen for food packaging, electronics manufacturing, or pharmaceutical processes, you can rely on the Hengyetong’s Nitrogen Generator to deliver high purity gas every time.

In addition to its performance and reliability, the Hengyetong’s Nitrogen Generator is also designed with cost-efficiency in mind. By producing nitrogen on-site, businesses can eliminate the need for expensive nitrogen gas deliveries and rental fees for cylinders. This not only reduces operating costs but also minimizes carbon footprint, making it a sustainable choice for environmentally conscious businesses.

The Hengyetong’s Automatic Low Cost High Purity Certificated Nitrogen Gas Generation Plant PSA Industrial Nitrogen Generator is a versatile and cost-effective solution for businesses seeking a reliable nitrogen supply. With its advanced technology, automatic operation, and high purity output, this generator is a valuable asset for any industrial operation. Experience the benefits of on-site nitrogen generation with Hengyetong - the trusted brand for quality and performance

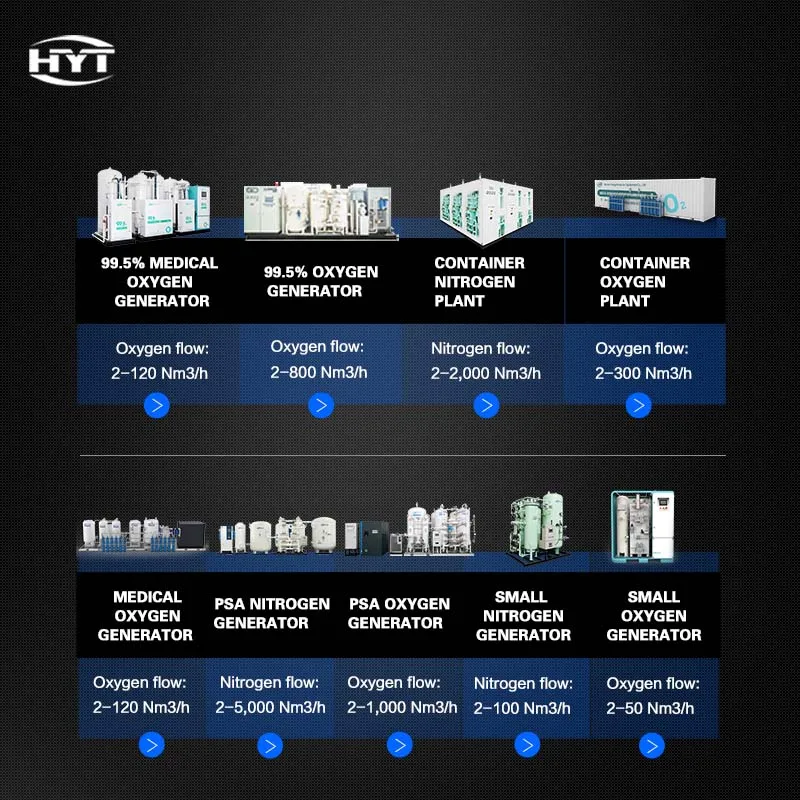

Model |

Dxygen Capacity - Nm³/min |

Purity |

CPN29 |

2-2000 |

99% |

CPN49 |

2-1500 |

99.99% |

CPN59 |

2-1000 |

99.999% |

CPN69 |

2-800 |

99.9999% |

Q: What the nitrogen purity of this machine can be achieved

We can provide 99%~99.9999% nitrogen purity

Q: The more information you kindly tell us, the better professional service we provide for you

a. What is the gas source you currently use? cylinder/dewar/liquid gas/other

b. Gas consumption? Nm3/h, L/min c. Required gas pressured. Required gas quality? eg:Maximum oxygen percentage, Maximum moisture content, etc

Q: Nitrogen equipment is safety

Definitely! Nitrogen/Oxygen generator is a kind of air separation device under normal temperature, it can supply stable and continuous nitrogen/oxygen gas, it doesn't need any high-pressure cylinders and liquid cylinders which have potentially dangerous; so we don't need to worry about no-timely supply due to special circumstance

Q: The producing nitrogen/oxygen is gaseous state or liquid state

Our nitrogen/oxygen equipment use PSA air separation technology under normal temperature, with no-lowtemperature operation, the temperature of nitrogen/oxygen product is close to ambient temperature

Q: How long is the nitrogen/oxygen equipment service life

Generally speaking, industrial equipment service life is depend on daily maintenance. under normal maintenance, our equipment can well running for more than 10 years

Q: How is the maintenance time of oxygen equipment

For Air purification module: the primary filters need to replace after 4000h normal operation; precision, extra-precision filters need to replace after 8000h,12000h normal operation: valve seal seal for 16000h;other filters depend on actual operation.