High Purity Low Cost Certificated Safe Nitrogen Generation Plant PSA Industrial Nitrogen Generator for Laser Cutting

- Overview

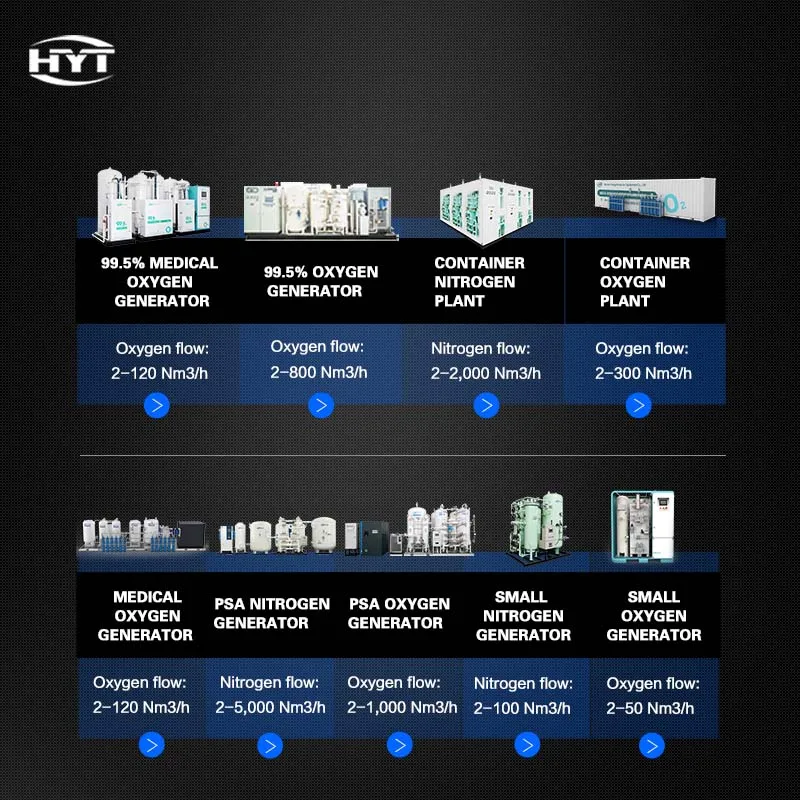

- Recommended Products

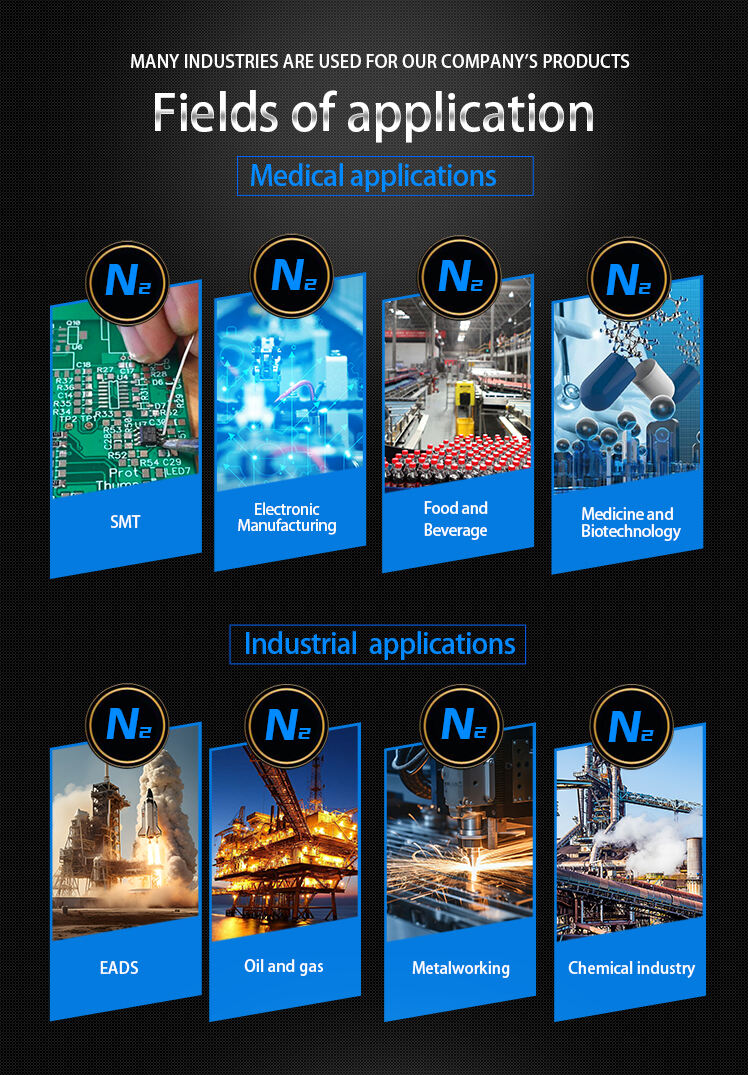

Introducing, the Hengyetong’s High Purity Low Cost Certificated Safe Nitrogen Generation Plant, the ultimate solution for industrial nitrogen generation.

This PSA Industrial Nitrogen Generator is designed specifically for applications such as laser cutting, where high purity nitrogen is essential for optimal performance. With its advanced technology and reliable components, this nitrogen generator is the ideal choice for businesses looking to streamline their operations and reduce costs.

The Hengyetong’s Nitrogen Generation Plant utilizes pressure swing adsorption (PSA) technology to separate nitrogen from the air, delivering a steady supply of high purity nitrogen at a fraction of the cost of traditional nitrogen tanks. This not only eliminates the need for frequent refills and deliveries, but also ensures a consistent supply of nitrogen at the necessary purity level for laser cutting and other industrial processes.

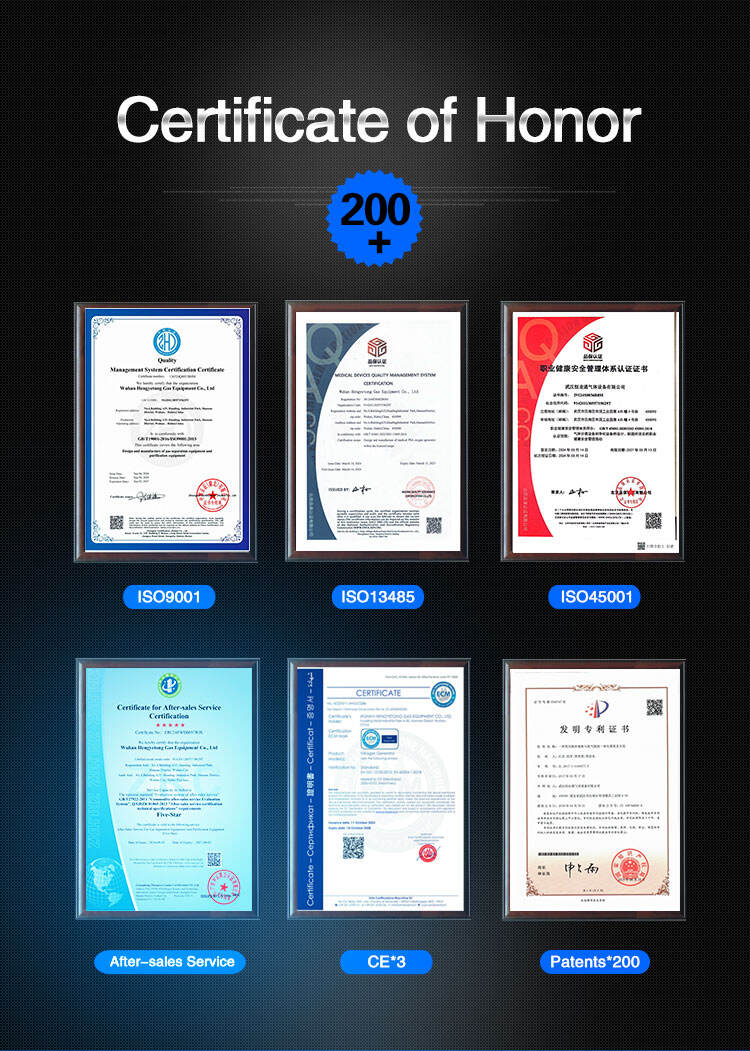

Safety is always a top priority, which is why the Hengyetong’s Nitrogen Generation Plant is equipped with multiple safety features to protect both the equipment and personnel. With its CE certification and strict adherence to international safety standards, you can trust that this nitrogen generator is reliable and secure.

The low cost of operation is another key advantage of the Hengyetong’s Nitrogen Generation Plant. By producing nitrogen on-site, businesses can significantly reduce their nitrogen expenses and eliminate the logistical challenges associated with storing and handling nitrogen tanks. This cost-effective solution ensures a quick return on investment and long-term savings for your business.

With its compact design and user-friendly interface, the Hengyetong’s Nitrogen Generation Plant is easy to install and operate. Whether you are a small business or a large industrial facility, this nitrogen generator can meet your specific nitrogen requirements with ease.

The Hengyetong’s High Purity Low Cost Certificated Safe Nitrogen Generation Plant offers a reliable, cost-effective, and efficient solution for businesses seeking to enhance their industrial processes. With its advanced technology, safety features, and low operating costs, this nitrogen generator is a game-changer for industries such as laser cutting. Upgrade your operations today with the Hengyetong’s Nitrogen Generation Plant

Model |

Dxygen Capacity - Nm³/min |

Purity |

CPN29 |

2-2000 |

99% |

CPN49 |

2-1500 |

99.99% |

CPN59 |

2-1000 |

99.999% |

CPN69 |

2-800 |

99.9999% |

Q: What the nitrogen purity of this machine can be achieved

We can provide 99%~99.9999% nitrogen purity

Q: The more information you kindly tell us, the better professional service we provide for you

a. What is the gas source you currently use? cylinder/dewar/liquid gas/other

b. Gas consumption? Nm3/h, L/min c. Required gas pressured. Required gas quality? eg:Maximum oxygen percentage, Maximum moisture content, etc

Q: Nitrogen equipment is safety

Definitely! Nitrogen/Oxygen generator is a kind of air separation device under normal temperature, it can supply stable and continuous nitrogen/oxygen gas, it doesn't need any high-pressure cylinders and liquid cylinders which have potentially dangerous; so we don't need to worry about no-timely supply due to special circumstance

Q: The producing nitrogen/oxygen is gaseous state or liquid state

Our nitrogen/oxygen equipment use PSA air separation technology under normal temperature, with no-lowtemperature operation, the temperature of nitrogen/oxygen product is close to ambient temperature

Q: How long is the nitrogen/oxygen equipment service life

Generally speaking, industrial equipment service life is depend on daily maintenance. under normal maintenance, our equipment can well running for more than 10 years

Q: How is the maintenance time of oxygen equipment

For Air purification module: the primary filters need to replace after 4000h normal operation; precision, extra-precision filters need to replace after 8000h,12000h normal operation: valve seal seal for 16000h;other filters depend on actual operation.