Ni ngapi majani ya PSA? Mjani wa PSA, kiambapo cha Pressure Swing Adsorption, ni kifani kikubwa kinachotumika kwa kufanya ujazo wa matano ndani ya mitaa ya kazi. Wao wanatumia mwongozo husio wa kuhakikisha matano yoyote kupitia mchanganyiko. Hii ni muhimu kwa kupunguza matano yoyote kama vile nitrogen, oxygen, na carbon dioxide. Viwanda vinginevyenyevisi hiviavyo vinahitaji matano haya ya kifani kwa kazi zao.

Mshambuli wa PSA zinatumika zaidi kwa kuweka nitrogen, mchango mrefu wao ni hupatikana kwa fedha ndogo zaidi kuliko tekniki hizo za leo. Hii ni sababu wakiolesha wanasajilia zile. Jikimu la Oxygen ya PSA za Hengyetong pia ni ndogo na rahisi kutengeneza, hivyo biashara inaweza kupanga nitrogen haraka bila uwekezaji mkubwa au nafasi.

Mipango ya PSA pia ni muhimu kwa kuongeza usafi wa bikarabonidi kwa ajili ya kifaa cha masafi. Wakati lililo katika mfano, bikarabonidi ni muhimu kwa mafunzi yanayotokana na maji pepe, na hivyo ndio sababu ya haja ya bikarabonidi safi ili kufanya. Jikimu la Nitrogen ya PSA kwa Hengyetong inaweza kusafisha bikarabonidi kutoka vya nguvu nyingine, kiongoziano hiki huweza kubadilisha tu kuwa kupakua bikarabonidi safi peke yake kwa kufanya mafunzi.

Mipangizo ya mitaa ya PSA yanatengenezwa kulingana na maombi ya mashirika yanayohitajika oxygen. Mitaa haya yanaweza kujengwa ili kupiga idadi ya oxygen ikiwa ni rahisi kwa kazi moja ili kuhifadhi operesheni na kupunguza uzalishaji. Mashirika yanaweza kuhakikisha kazi zao zina oxygen ya juhudi juu kwa kutumia Jikimu la Oxygen ya Kliniki hengyetong

Majani ya PSA huonyesha kuwa ni ramisi na mazingira, si tu kwa sababu ya usalama wa CO2, bali pia kwa sababu ya kupunguza karboni. Majani haya yanaweza kupunguza na kutengeneza magazo kama vile carbondioxide ili usiyoze kuenda ndani ya anga na kusababisha mabadiliko ya hali ya hewa. Teknolojia ya PSA inasaidia kupunguza magazo ya chini la anga kutoka katika viwanda ambavyo vinaweza kuweka mbali upya uzito wa karboni na kuunda siku jana sahihi.

Tunatoa safu kamili ya mifumo ya gesi inayotegemea teknolojia, ikiwemo Kizunguzungu cha Oksijeni cha Kimsingi, Mifumo ya Oksijeni ya Uwingu Mzuri, Vifaa vya Kutengeneza Nitrojeni, na Vifaa vya Ondoa CO₂, vinavyotolewa kama suluhisho uliojumuishwa na wa bei nafuu kwa mahitaji tofauti duniani kote.

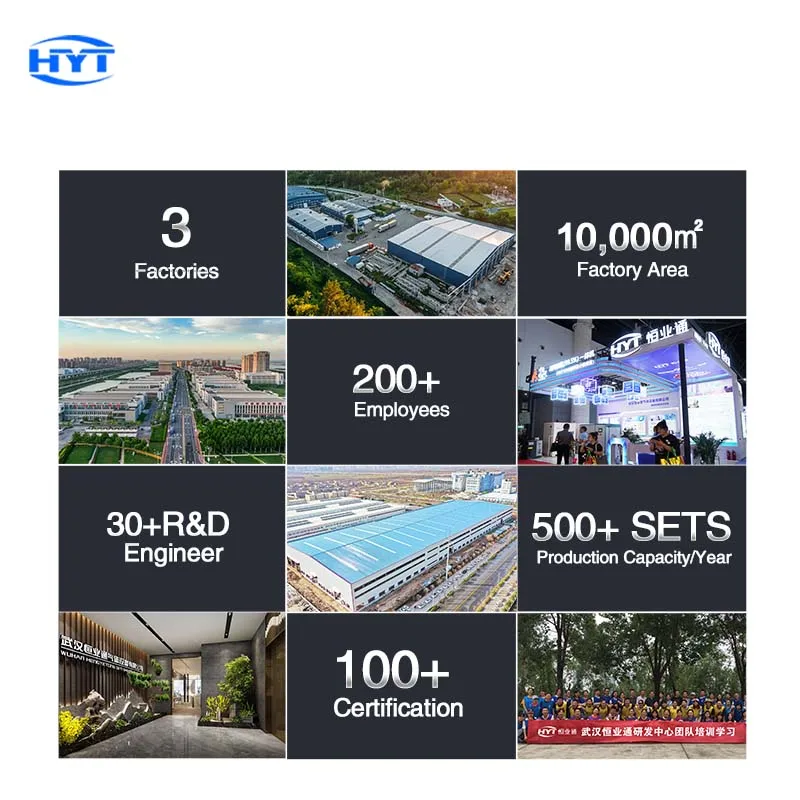

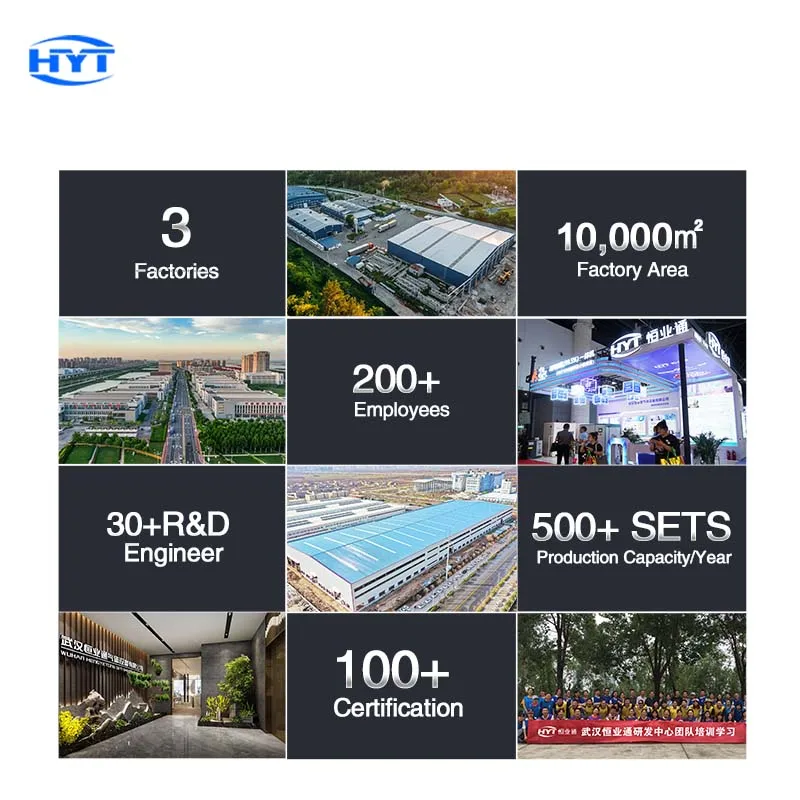

Kwa zaidi ya miaka 30 ya uzoefu unaosimama, tunamkabidhiwa kama shirika la juu la teknolojia linalospecialisha katika utafiti wa maombile na uundaji wa vifaa vya kugawanya hewa, ambavyo hutengeneza gesi, tunachokufanya kuwa watendaji wa kuaminika katika sekta ya suluhisho la gesi ya PSA.

Kama entreprise ya teknolojia ya juu ya kiwilaya, tunaunganisha ujuzi wa kiufundi uthibitishwa na mkazo wa kimataifa unaobainika, kutoa suluhisho bora zaidi na ambao unasimama mbele wa wateja wa duniani kote.

Tunajitolea kwa utafiti na uvumbuzi wa mara kwa mara, tunachukua falsafa ya maendeleo ya "kumunganisha teknolojia ya mbele ili kujenga chapa ya kimataifa", kuhakikisha bidhaa zetu zinakidhi viwango vya juu vya utendaji na uaminifu kwa masoko ya kimataifa.