là quá trình sản xuất khí nitơ từ không khí. Điều này đạt được bằng cách loại bỏ các khí khác, chẳng hạn như oxy và carbon dioxide, cho đến khi còn lại nitơ. Ni...">

Sản xuất nitơ đang sản xuất khí nitơ từ không khí. Điều này được thực hiện bằng cách loại bỏ các khí khác, như oxy và dioxide carbon, cho đến khi chỉ còn lại nitơ. Khí nitơ sau đó được lưu trữ trong các bồn chứa và được sử dụng cho nhiều mục đích khác nhau.

Dưới đây là một số lý do thuyết phục ủng hộ việc sử dụng nitơ trong các hệ thống sản xuất . Một lý do quan trọng là tiết kiệm chi phí. Thay vì mua khí nitơ tại cửa hàng, các doanh nghiệp có thể sản xuất nitơ của riêng mình ngay tại chỗ. Như vậy, họ không cần phải lo lắng về việc hết khí hoặc chờ đợi giao hàng. Hệ thống tạo khí nitơ cũng thân thiện với môi trường vì nó loại bỏ việc vận chuyển và đóng gói khí nitơ.

Quá trình tạo khí nitơ được gọi là hấp phụ dao động áp suất. Quy trình này sử dụng một thiết bị thổi không khí qua bộ lọc độc quyền chỉ cho phép khí nitơ đi qua. Khí nitơ tinh khiết sau đó được cô lập và xử lý sau khi các khí khác bị loại bỏ. Đây là phương pháp rất hiệu quả và tiết kiệm chi phí, đã tìm thấy vị trí của mình trong nhiều ngành công nghiệp.

Các hệ thống tạo khí nitơ có thể mang lại lợi ích cho vô số ngành công nghiệp. Các lĩnh vực khác bao gồm đóng gói thực phẩm, sản xuất điện tử, dược phẩm và dầu khí. Khí nitơ được sử dụng trong đóng gói thực phẩm để kéo dài độ tươi của chúng. Khí nitơ ngăn ngừa rỉ sét và hàn trong điện tử. Trong ngành dược phẩm, nitơ bảo vệ các vật liệu nhạy cảm khỏi bị nhiễm bẩn. Trong lĩnh vực dầu khí, nitơ được sử dụng để làm sạch đường ống và bồn chứa.

Các yếu tố cần xem xét như mức độ tinh khiết, tốc độ dòng chảy và yêu cầu về áp suất nên được cân nhắc khi chọn một hệ thống sản xuất nitơ . Mỗi loại ngành công nghiệp đều có những nhu cầu độc đáo riêng, vì vậy việc chọn lựa một hệ thống đáp ứng được những nhu cầu cụ thể đó là rất quan trọng. Hãy cân nhắc vị trí lắp đặt hệ thống, kích thước của chúng và nơi phù hợp để đặt chúng. Bằng cách chú ý đến tất cả các yếu tố này, các công ty sẽ chọn được một hệ thống tạo khí nitơ phù hợp với mục đích của mình.

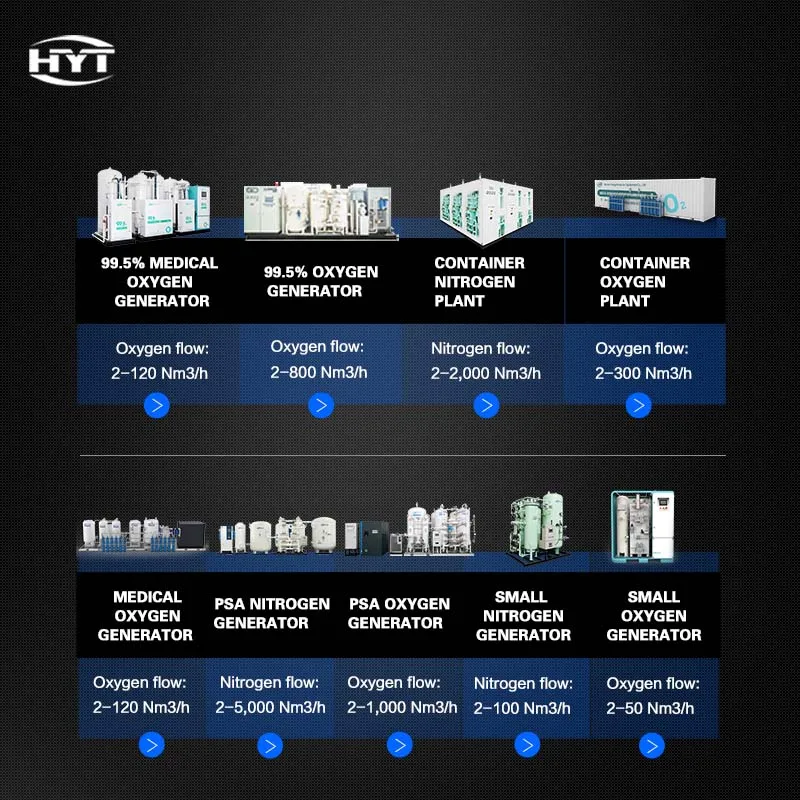

Chúng tôi cung cấp đầy đủ các hệ thống khí tiên tiến, bao gồm Máy phát Oxy y tế, Hệ thống Oxy độ tinh khiết cao, Máy phát Nitơ và Thiết bị loại bỏ CO₂, mang đến các giải pháp tích hợp và tiết kiệm chi phí cho nhu cầu toàn cầu đa dạng.

Được công nhận là doanh nghiệp công nghệ cao cấp tỉnh, chúng tôi kết hợp chuyên môn kỹ thuật được chứng nhận với chiến lược toàn cầu tiên phong, cung cấp các giải pháp tách khí phù hợp và tiên tiến nhất đến khách hàng trên toàn thế giới.

Cam kết liên tục nghiên cứu và phát triển cũng như đổi mới, chúng tôi áp dụng triết lý phát triển "tích hợp công nghệ tiên tiến để xây dựng thương hiệu toàn cầu", đảm bảo sản phẩm đáp ứng các tiêu chuẩn cao nhất về hiệu suất và độ tin cậy cho thị trường quốc tế.

Với hơn 30 năm kinh nghiệm chuyên sâu, chúng tôi được công nhận là doanh nghiệp công nghệ cao chuyên nghiên cứu ứng dụng và sản xuất thiết bị khí phân tách không khí, giúp chúng tôi trở thành nhà tiên phong đáng tin cậy trong ngành giải pháp khí PSA.