Containerized Free Installation Automatic High Purity Oxygen Generation System PSA Medical Oxygen Generator

- Overview

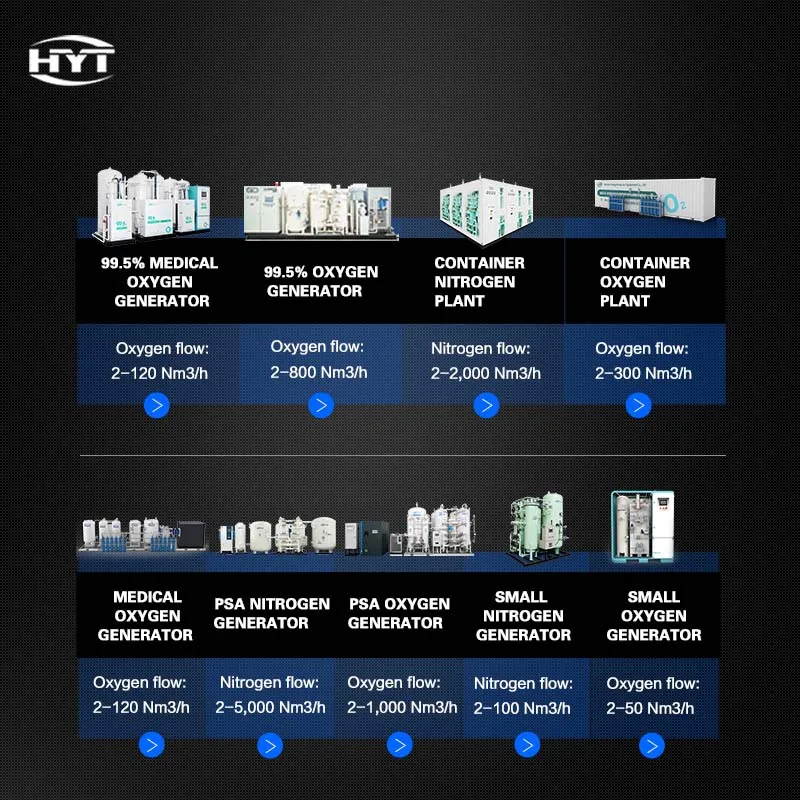

- Recommended Products

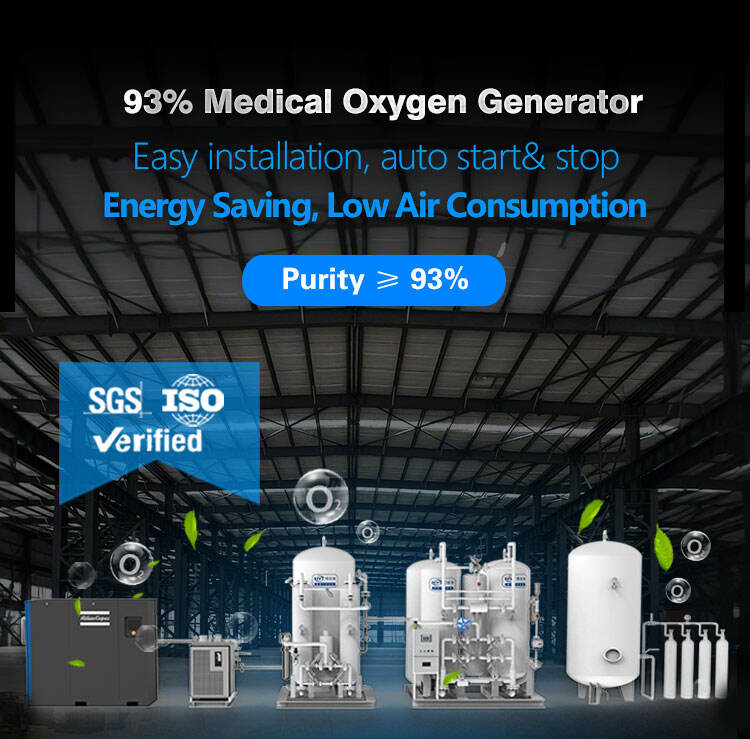

Introducing, the Hengyetong’s Containerized Free Installation Automatic High Purity Oxygen Generation System PSA Medical Oxygen Generator. This cutting-edge system is a must-have for hospitals, clinics, and medical facilities looking to provide high-quality oxygen to their patients.

With a sleek and modern design, the Hengyetong’s Medical Oxygen Generator is not only efficient but also easy to install. Its containerized design means that it can be set up quickly and without the need for complex installations. This makes it the perfect solution for facilities looking to upgrade their oxygen supply without disrupting their daily operations.

The Automatic High Purity Oxygen Generation System utilizes Pressure Swing Adsorption (PSA) technology to produce medical-grade oxygen with purity levels exceeding 93%. This means that the oxygen produced is safe and suitable for use in a wide range of medical procedures and treatments.

One of the key features of the Hengyetong’s Medical Oxygen Generator is its automatic operation. Once installed, the system can run continuously without the need for manual intervention. This ensures a steady and reliable supply of oxygen to meet the demands of a busy medical facility.

In addition to its automatic operation, the Hengyetong’s Medical Oxygen Generator is also incredibly energy-efficient. It is designed to minimize energy consumption while maximizing oxygen production, helping to reduce operating costs for medical facilities.

Safety is a top priority when it comes to medical oxygen generation, which is why the Hengyetong system is equipped with advanced safety features to protect both patients and staff. These include built-in sensors and alarms to monitor oxygen purity levels and alert users to any potential issues.

The Hengyetong’s Containerized Free Installation Automatic High Purity Oxygen Generation System PSA Medical Oxygen Generator is a top-of-the-line solution for medical facilities looking to ensure a reliable and high-quality oxygen supply. With its easy installation, automatic operation, and advanced safety features, this system is sure to meet the needs of even the most demanding medical environments. Trust in Hengyetong for all your medical oxygen generation needs

Model |

Orygen Purity |

Dxygen Capacity - Nm³/min |

Air Compressor - KW |

Suitable Scale - Bed/pec |

Power - KW |

MPS93-2 |

≥93 |

5 |

7.5 |

150 |

8.0 |

MPS93-10 |

≥93 |

10 |

11 |

300 |

12 |

MPS93-50 |

≥93 |

50 |

45 |

1500 |

48 |

MPS93-120 |

≥93 |

120 |

110 |

3600 |

115 |

Q: What the nitrogen purity of this machine can be achieved

We can provide 99%~99.9999% nitrogen purity

Q: The more information you kindly tell us, the better professional service we provide for you

a. What is the gas source you currently use? cylinder/dewar/liquid gas/other

b. Gas consumption? Nm3/h, L/min c. Required gas pressured. Required gas quality? eg:Maximum oxygen percentage, Maximum moisture content, etc

Q: Nitrogen equipment is safety

Definitely! Nitrogen/Oxygen generator is a kind of air separation device under normal temperature, it can supply stable and continuous nitrogen/oxygen gas, it doesn't need any high-pressure cylinders and liquid cylinders which have potentially dangerous; so we don't need to worry about no-timely supply due to special circumstance

Q: The producing nitrogen/oxygen is gaseous state or liquid state

Our nitrogen/oxygen equipment use PSA air separation technology under normal temperature, with no-lowtemperature operation, the temperature of nitrogen/oxygen product is close to ambient temperature

Q: How long is the nitrogen/oxygen equipment service life

Generally speaking, industrial equipment service life is depend on daily maintenance. under normal maintenance, our equipment can well running for more than 10 years

Q: How is the maintenance time of oxygen equipment

For Air purification module: the primary filters need to replace after 4000h normal operation; precision, extra-precision filters need to replace after 8000h,12000h normal operation: valve seal seal for 16000h;other filters depend on actual operation.